Third-year students of Industrial Process Engineering at the Faculty of Metals Engineering and Industrial Informatics, AGH University of Science and Technology, under the supervision of Mikołaj Bernasowski, PhD, DSc and Padhamnath Pradeep PhD, crossed the threshold of our research facilities, where ideas, technologies, and solutions shaping the future of the Polish materials industry are born every day.

The visit was organized as part of activities aligned with the Social Responsibility of Science, aimed at bringing real research closer to young engineers and opening laboratories that are usually the domain of research teams.

Hydrogen First – Hydrogen Metallurgy Laboratory

The first stop was a space where hydrogen is not just a buzzword about the energy future but a tool for everyday experiments.

In the Hydrogen Metallurgy Laboratory of the Raw Materials Processes Research Group, students were welcomed by:

- Janusz Stecko, DEng

- Alicja Szemalikowska, MSc Eng.

They introduced the students to the world of ore reduction, material purification, and reactions in which hydrogen plays a leading role. The students had the opportunity to see up close equipment where processes occur at temperatures more reminiscent of the Earth’s interior than a university laboratory.

Behind the Scenes of Production – Raw Materials Process Technologies

The next stage involved a meeting with representatives of the Raw Materials Processes Research Group.

The following institutions presented their research facilities:

- Mariusz Borecki, DEng

- Mateusz Dudek, MSc Eng.

They presented their research infrastructure and explained methods of physically simulating metallurgical processes, showing how engineering precision is combined with design creativity. Students observed workstations where innovative technological processes are developed from concept to industry.

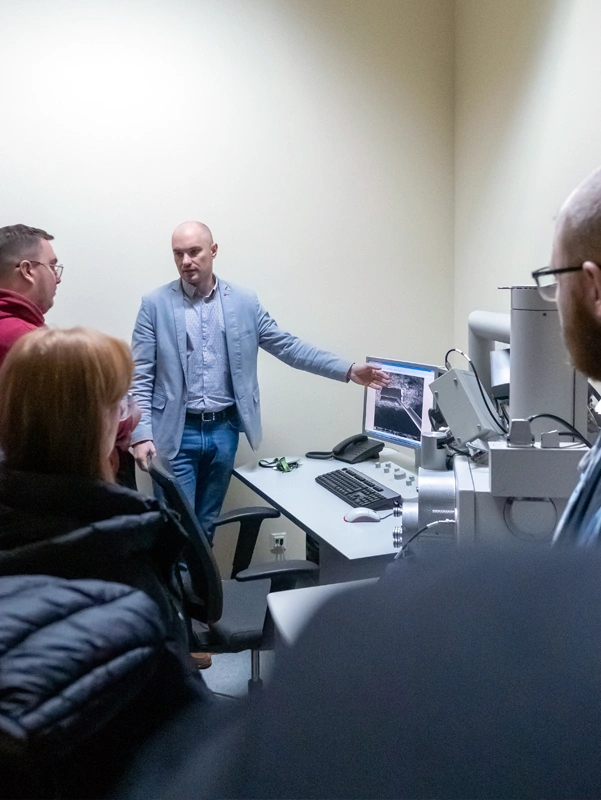

Materials Under the Microscope – Materials Research

In the world of microstructures and material analysis, students were welcomed by Michał Szulc, MSc Eng who introduced the activities of the Materials Research Group. Participants had the opportunity to see equipment used to study the properties and behavior of materials, from standard alloys to advanced engineering materials. Testing the strength of materials exposed to high temperatures, with applications in modern energy technologies.

Analytical Chemistry – From First Contact to a Full Range of Services

The group then visited the Analytical Chemistry Laboratory.

Michał Kubecki, DEng, welcomed the students and introduced them to the world of precise analyses, where even a picogram or microgram can tell the material’s story.

Next Marta Kubiczek, DEng, presented the laboratory’s range of services — from elemental and impurity analyses, through chemical speciation, to advanced methods of composition identification. Students learned about the importance of analytical support in materials research and the critical role of accuracy, calibration, and sensitivity in applied techniques.

Properties, Structure, and Industrial Challenges

The next presentation was led by:

- Radosław Swadźba, PhD, DSc

- Karol Sówka, DEng,

The researchers discussed the tasks of the Materials Properties and Structure Research Group and collaboration with companies for whom advanced analyses are conducted. Students could see the full research cycle — from a company’s problem, through experiment planning, to the interpretation of results that directly influence innovation in the Polish industry.

Simulations of the Future – Computational View of Technological Processes

Finally, Jarosław Opara, DEng, introduced the group to a world where technological processes can be “visualized” before they are physically implemented.

In the Technological Processes Simulation Group, the computer acts as furnace, press, rolling mill, and laboratory simultaneously. Students explored the capabilities of modern numerical tools and their growing role in optimizing industrial processes.

Open Science – Inspiration for the Future

Inspiration, practical knowledge, and conversations with experts passionate about their work. Students had the opportunity to see the most advanced research facilities and understand that engineering is not only formulas and models but, above all, the people who know how to use them.

This is how Social Responsibility of Science is realized — by providing insight into research processes, laboratories, and knowledge to those who will soon continue to develop them.