Laboratory of Materials’ Resistance to Stress Cracking in Corrosive Environments – SSC Test

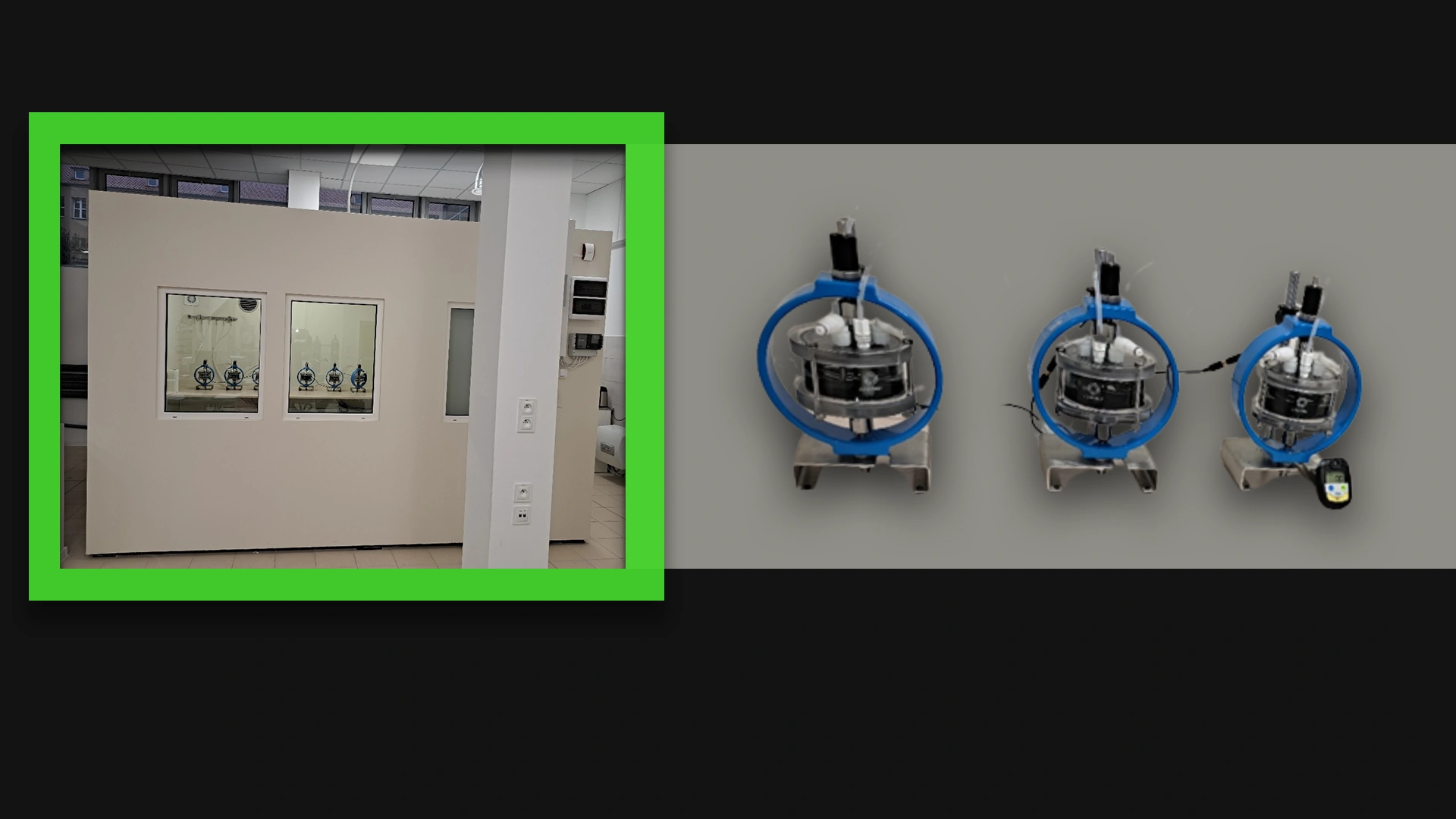

In 2024, Sieć Badawcza Łukasiewicz – Górnośląski Instytut Technologiczny launched a new research laboratory related to the resistance of metals to stress cracking in corrosive environments.

It is the only laboratory of this type currently operating in Poland. The SSC (Sulfide Stress Cracking) method is a form of testing the susceptibility of a material to hydrogen cracking. It is the only laboratory of this type currently operating in Poland. The SSC (Sulfide Stress Cracking) method is a form of testing the susceptibility of a material to hydrogen cracking. It is related to the brittleness of metals caused by the diffusion of atomic hydrogen in corrosive processes. The absorption of hydrogen atoms is facilitated by the presence of sulphides. This method is used in qualification tests of materials used in transmission transport and is compliant with the NACE TM0177 and PN-EN ISO 15156-1 standards. In the SSC method, the sample is subjected to tensile stresses up to 80-90% of the yield strength of the tested material and placed in a chamber filled with an aqueous solution of acidic sodium chloride. During the test, hydrogen sulphide H2S is supplied to the chamber filled with the solution. It is also possible to conduct tests using other gases and their mixtures, including hydrogen mixtures.